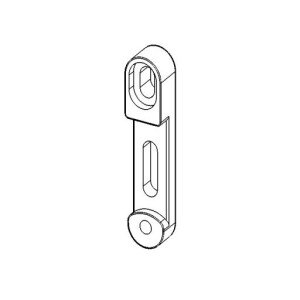

dragonfly/stingray spare - nº41b - x2 eccenter assy ( preset long 4.5 mm)

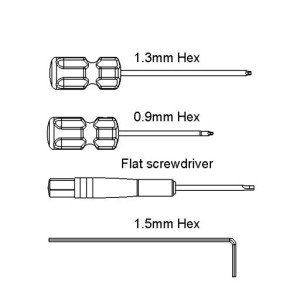

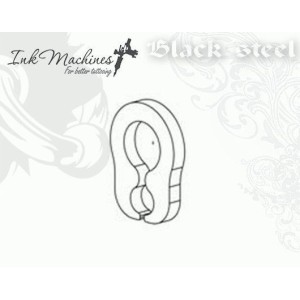

Dragonfly spare part. Fits all Dragonfly machines. Preset for 4.5mm long travel. It can also be adjusted with the precision tool kit #90 from 2.6 to 4.5 mm. Note that you will also need the #55 - Circlip to replace this part. Use the circlip pliers to remove the circlip and push out the connecting pin. Loosen the eccentric from the motor shaft with the smallest 0.9 mm allen key. There are two screws on the standard eccentric, one for the motor shaft and one for the bearing shaft. You only need to use the motor shaft screw. Install the new assembly on the motor shaft making sure the screw ends on the flat part of the shaft and tighten it securely. Check that the connecting rod lines up correctly with the groove in the piston. This is important, if it doesn't line up correctly it won't work properly and you may have to readjust the location of the motor. In this case, consult the manual or send it to the technical service. If OK, align the upper bearing with the piston bore and insert the connecting pin and install the circlip.

DGFR-41B Dragonfly Spare Part- Nº41B - X2 Eccenter Assy ( Preset Long 4.5 mm)

100% secure payments

100% secure payments

From 121€

100% safe

Dragonfly spare part. Fits all Dragonfly machines. Preset for 4.5mm long travel. It can also be adjusted with the precision tool kit #90 from 2.6 to 4.5 mm. Note that you will also need the #55 - Circlip to replace this part. Use the circlip pliers to remove the circlip and push out the connecting pin. Loosen the eccentric from the motor shaft with the smallest 0.9 mm allen key. There are two screws on the standard eccentric, one for the motor shaft and one for the bearing shaft. You only need to use the motor shaft screw. Install the new assembly on the motor shaft making sure the screw ends on the flat part of the shaft and tighten it securely. Check that the connecting rod lines up correctly with the groove in the piston. This is important, if it doesn't line up correctly it won't work properly and you may have to readjust the location of the motor. In this case, consult the manual or send it to the technical service. If OK, align the upper bearing with the piston bore and insert the connecting pin and install the circlip.

It may interest you

Dragonfly/Stingray Replacement - #18 Adjustment Screw

Dragonfly/Stingray Spare - Nº90 Precision Tool Kit

Dragonfly/Stingray Spare - Nº25 Circlip

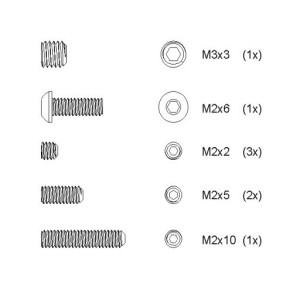

Dragonfly/Stingray Spare - Nº50 Screw Kit ( Dragonfly)

Dragonfly/Stingray Spare - #71B Alu Bearing Rod ( Stingray)

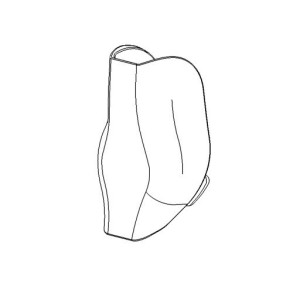

Dragonfly/Stingray Spare - Nº96 Cover For Dragonfly

Review sent